In order to ensure the safe operation of the power system and understand the operating status of the power system, it is necessary to monitor various operating parameters of the energy consumption management system in real-time.

The energy management system has successfully and efficiently completed this task, and has become an important component of power system automation, becoming one of the important measures to ensure the safe operation of the power system.

The energy consumption management system of Yike utilizes computer, metering protection devices, and bus technology to centrally manage real-time data, switch status, and remote control of medium and low voltage distribution systems. This energy management system can provide enterprises with an overall solution of "monitoring integration".

This system is independently developed by senior developers who have been engaged in power software design for many years. It uses WINDOW2000/NT/XP as the operating platform and large relational databases such as OracleSQL Serve2000 as the database platform. The data is secure and accurate, and the system has automatic backup function, without the need for manual data organization; The rich configuration software package can accurately and real-time describe the on-site situation by cooperating with the network and real-time library.

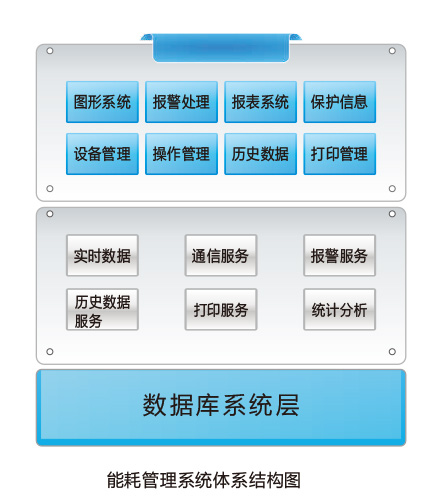

Energy consumption management system architecture diagram

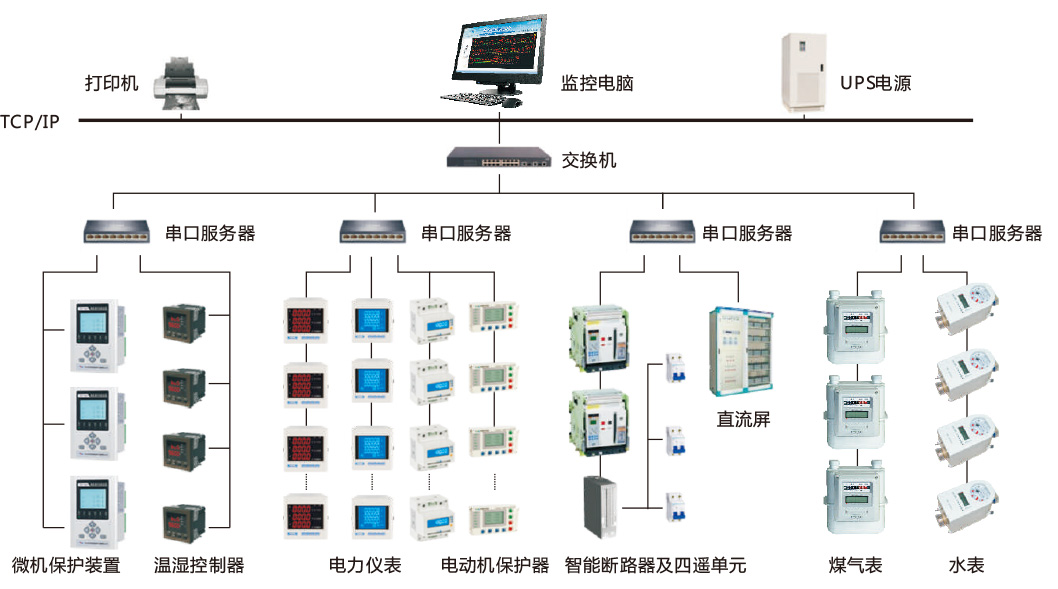

System Architecture

Based on the Client/Server mechanism, following international standards, and meeting the design requirements of open systems, IKE has achieved openness from the system platform layer to the application layer; It provides good interoperability and distribution, facilitates the sustainable expansion of user level functions, and enables it to adapt to the ever-changing business needs of the computer room monitoring system automation; Adopting flexible software and hardware configuration schemes, it can form various scheduling, distribution scheduling, or integrated management systems with different scales and requirements.

The energy consumption management system of Yike is designed following a three-layer architecture, which is divided into a data system layer, an application service layer, and a customer application layer. Each module in the three-layer structure works together.

The database system layer is responsible for storing system parameters, data, and historical record data, while completing classification statistics and organizing historical data. The C/S system structure of the system sampling standard is that the client is only responsible for requesting application tasks. The request information is sent to the designated application server through the system's network subsystem, and the application server completes the logical functions they care about. The advantage of adopting this approach is that the client only cares about the customized tasks and interface display results, and the specific business logic is completed by the application server, thereby ensuring the modularization of development and the maintainability of the system.

Adopting a unified access interface to achieve standardized access. All customer application layer functions, application servers, and database system modules have adopted standard and unified development methods and access interfaces. The customer application server and database system modules have adopted standard and unified development methods and access interfaces. The customer application layer function modules and application server functions do not rely on host nodes in deployment, and can be freely configured according to user requirements, that is, they can run in a host system, It can also be distributed and deployed based on functionality.

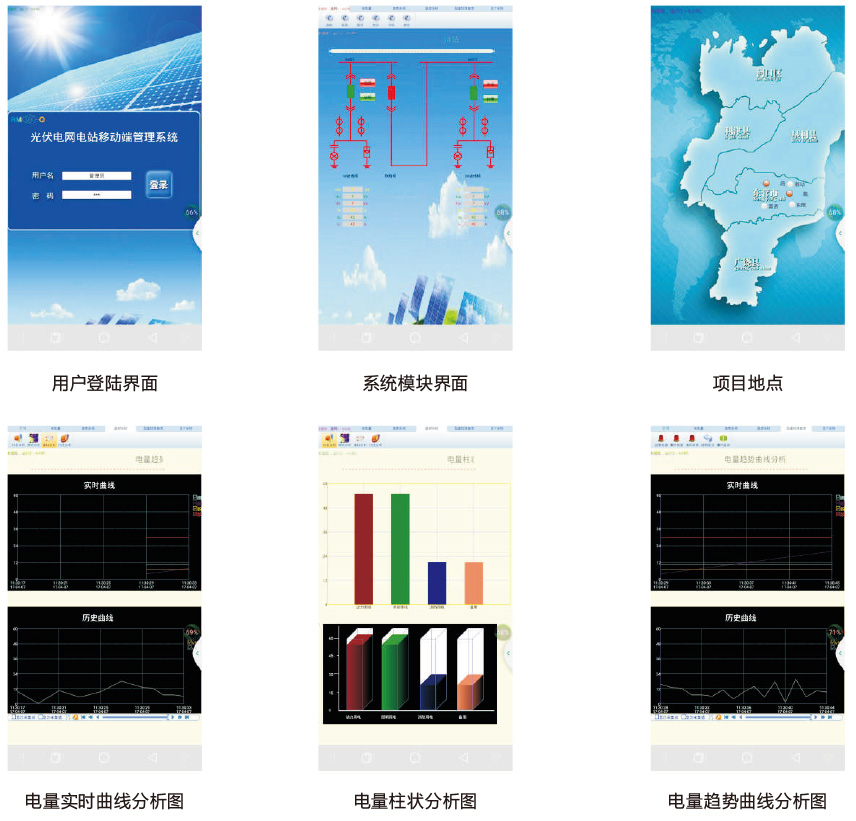

Real time monitoring of mobile apps

Monitoring configuration software functions

TCP/IP network protocol is currently the most popular and stable network protocol. The system has developed a dedicated communication layer on top of the TCP/IP network protocol, reducing the utilization of system resources.

The energy consumption management system software of Yike utilizes computers, communication equipment, metering protection devices, etc., providing a basic platform for real-time data collection, switch status detection, and remote control of the system. The network structure of the system is composed of three parts: management layer (station control layer), communication layer (intermediate layer), and interval layer (on-site monitoring layer).

user management

This software can grant different permissions to users of different levels, thereby ensuring the security and reliability of the system during operation. For the closing/opening operation of an important circuit, in addition to the operator level user entering the operation password, the engineer level user also needs to input the confirmation password before completing the operation.

The interface of this module is shown in the figure:

Data collection and processing

This system can collect various electrical parameters and switch status of on-site equipment in real time and timing (including three-phase voltage, current, power, power factor, frequency, electrical energy, temperature, switch position, equipment operation status, etc.), and display the collected data directly or generate new intuitive data information through statistical calculations (total system power, maximum load value, upper and lower limits of power factor, etc.), And store important information in a database.

The interface of this module is shown in the following figure:

Trend curve analysis

The system provides real-time curve analysis, historical trend curve analysis, and daily, monthly, and annual bar chart analysis; Analyze the current load operation status of the circuit by calling the real-time curve interface of the relevant circuit. The historical trend of the system refers to the ability of the system to view the historical trend of all stored data, facilitating engineering personnel to conduct quality analysis of the monitored distribution network.

The interface of this module is shown in the following figure:

Report Management

The system has a standard electricity report format and can design a report format that meets user needs according to their needs. The system can automatically perform statistics. It can automatically generate various types of real-time operation reports, historical reports, event fault and alarm record reports, operation record reports, etc. It can query and print system records and all data values, and automatically generate daily, monthly, and annual electricity reports.

The interface of this module is shown in the following figure:

Real time electrical parameters

The system provides a real-time display function for electrical parameters, which can display the electrical parameters of different electrical equipment in real-time according to user needs, and can print out relevant data.

The interface of this module is shown in the following figure:

Event recording and fault alarm

The system has a detailed recording function for all user operations, switch displacement, parameter exceeding limits, and other actual user needs events, including the time and location of the event occurrence, whether the current duty personnel have confirmed the event, etc. It also has a sound alarm function for switch displacement, parameter exceeding limits, and other information. At the same time, it automatically sends control commands or prompts the duty personnel to quickly troubleshoot the operating equipment.

Power monitoring instruments should be selected for energy management systems

Power monitoring instruments are designed for the power monitoring needs of power systems, industrial and mining enterprises, public facilities, and intelligent large public buildings. It can measure all commonly used power parameters with high precision, such as three-phase voltage, three-phase current, active power, reactive power, frequency, power factor, four-quadrant electrical energy, etc. It uses a high visibility LCD to display the instrument measurement parameters and the operation information of the power grid system. Power monitoring instruments have a wide range of functions and models, and their prices vary. Therefore, they should be reasonably selected to achieve better cost-effectiveness.

The configuration of power monitoring instruments in the energy consumption management system has significant advantages such as simple implementation and low investment. It can conveniently and real-time monitor the operation status of the distribution system, unify the management of on-site electrical equipment, and avoid the tedious work of staff recording on site. The system manages and analyzes the historical operation data and status of various electrical equipment, making it easy for maintenance personnel to clarify the equipment status, Develop a detailed equipment maintenance plan to reduce staff and improve efficiency.

Energy Consumption Management System for Instrumental Technology - Solutions

The number of monitoring points, the distance between monitoring points and the monitoring room, and the real-time requirements of users affect the network architecture. Solutions will be customized according to the specific situation of customers.

Energy Consumption Management System of Instrumental Technology - Engineering Case

The Advantages of Energy Management Systems

24-hour real-time monitoring, achieving centralized management and control, greatly saving manpower for power line inspection.

Visually view real-time parameters through the main wiring diagram module.

The report module can automatically generate daily/monthly/annual reports; Easy for customers to view.

The curve analysis module intelligently calculates energy consumption, measures electrical energy by item, identifies high energy consuming devices, helps users allocate energy usage structures reasonably, and ultimately achieves energy-saving effects.

Quickly respond to line faults and improve fault resolution efficiency.

This management system has practicality, security, stability, scalability, and ease of maintenance.

The configuration of power monitoring instruments in the power monitoring system has significant advantages such as simple implementation and low investment. It can conveniently and real-time monitor the operation status of the distribution system, unify the management of electrical equipment on site, and avoid the tedious work of staff recording on site. The system manages and analyzes the historical operation data and status of various electrical equipment, making it easy for maintenance personnel to clarify the equipment status, Develop a detailed equipment maintenance plan to reduce staff and improve efficiency.

network structure

Network structure diagram of the energy consumption management system of Yike